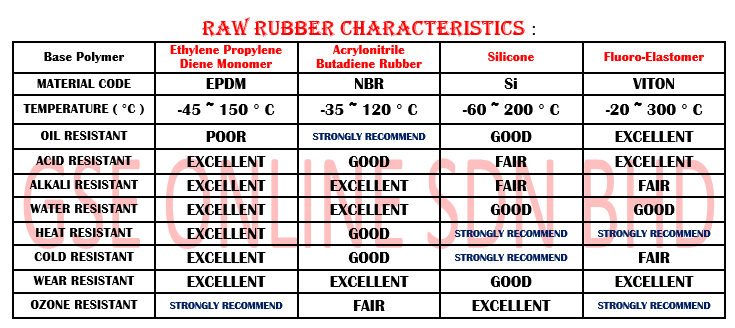

Rubber Characteristics :-

Submit ExpressSearch Engine Marketing

Note :

Customer to evaluate use of our products before placing order from us .

NO RETURN ALLOW .

Customer to evaluate use of our products before placing order from us .

NO RETURN ALLOW .

Rubber Sealing Products For Industrial Use

( We custom made extrusion rubber profiles and press molded rubbers ) - solid ( HD ) rubber and sponge ( LD ) rubber types.

Rubber description :

1) Available material : Silicone , EPDM , NBR , Viton etc.

2) Made of durable high grade rubber

3) Custom made of any Extrusion Shapes.

4) Type of Manufacturing :-

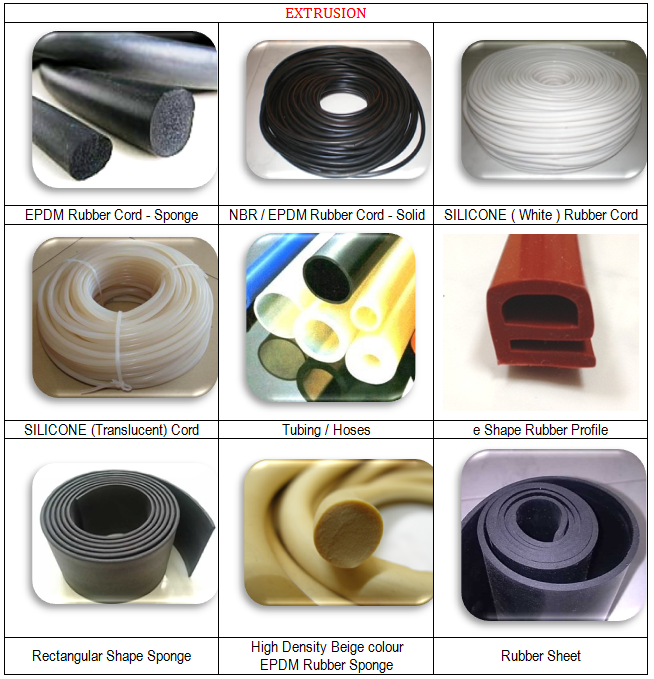

( a ) Extrusion - for custom made parts like cords , seals etc.

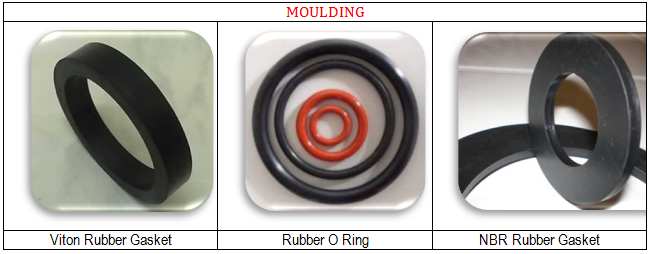

( b ) Press Moulding - gaskets etc.

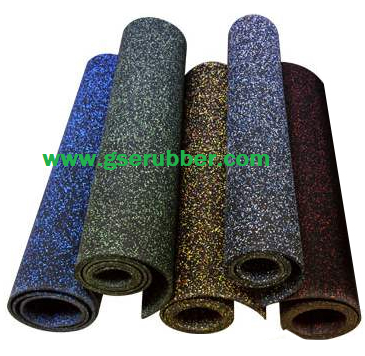

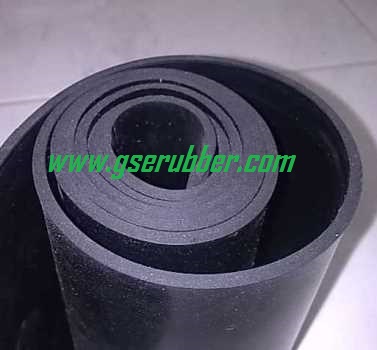

( c ) Calendering - for roll form rubbers.

Basic Synthetic ( Petro - Chemical ) Rubber Introduction :-

example , What Makes an O Ring ?

O-rings are manufactured from a variety of elastomers which are blended to form compounds. These compounds exhibit unique properties such as resistance to certain fluids, temperature extremes, and life. Shelf-life of an O-Ring depends upon the characteristics of each elastomer present in the compound and also environmental conditions. With optimum packaging and storage conditions,

Silicone Rubber ( FDA compliant )

Silicone rubbers are a group of synthetic elastomers noted for their

(1) resilience over a very wide temperature range,

(2) outstanding resistance to ozone and weathering, and

(3) excellent electrical properties.

General Working Temperature Range: - 60° C to +200° C

Silicon Rubber has great cold flexibility as well as high thermal resistance. It has excellent dielectric properties and very good resistance to attack by oxygen, ozone and sunlight. It has poor strength & tear resistance to mineral oils.

EPDM is ideal for outdoor applications because of its excellent resistance to ozone, oxidants, UV exposure and severe weather conditions.

It is highly recommended for applications where the elastomer will have excessive exposure to the environment . General Working Temperature Range: - 45° C to +150° C

Other outstanding characteristics of EPDM RUBBER include excellent color stability, heat resistance, and dielectric qualities.

EPDM is not recommended for applications involving petroleum derivatives.

EPDM is generally attacked by mineral oils, solvents, and aromatic hydrocarbons.

Nitrile, Buna N , or NBR

Nitrile is the most widely used elastomer in the seal industry.

The popularity of nitrile is due to its excellent resistance to petroleum products and its ability to be compounded for service over a temperature range of - 35°C to +120°C . A Modified NBR-Premier has a withstand short term temperature of - 35°C to +200°C .

Nitrile is a copolymer of butadiene and acrylonitrile. it has excellent resistance to mineral oil, greases, water, hydrocarbon fuels, compression set resistance and good elastic properties, it is not suitable to automotive brakes fluid.

Common Rubber Applications :-

NBR- Nitrile is generally resistant to many hydrocarbons, fats, oils, greases, hydraulic fluids and chemicals, but can be attacked by ozone, ketones, esters, aldehydes, chlorinated and nitro hydrocarbons.

( We custom made extrusion rubber profiles and press molded rubbers ) - solid ( HD ) rubber and sponge ( LD ) rubber types.

Rubber description :

1) Available material : Silicone , EPDM , NBR , Viton etc.

2) Made of durable high grade rubber

3) Custom made of any Extrusion Shapes.

4) Type of Manufacturing :-

( a ) Extrusion - for custom made parts like cords , seals etc.

( b ) Press Moulding - gaskets etc.

( c ) Calendering - for roll form rubbers.

Basic Synthetic ( Petro - Chemical ) Rubber Introduction :-

example , What Makes an O Ring ?

O-rings are manufactured from a variety of elastomers which are blended to form compounds. These compounds exhibit unique properties such as resistance to certain fluids, temperature extremes, and life. Shelf-life of an O-Ring depends upon the characteristics of each elastomer present in the compound and also environmental conditions. With optimum packaging and storage conditions,

Silicone Rubber ( FDA compliant )

Silicone rubbers are a group of synthetic elastomers noted for their

(1) resilience over a very wide temperature range,

(2) outstanding resistance to ozone and weathering, and

(3) excellent electrical properties.

General Working Temperature Range: - 60° C to +200° C

Silicon Rubber has great cold flexibility as well as high thermal resistance. It has excellent dielectric properties and very good resistance to attack by oxygen, ozone and sunlight. It has poor strength & tear resistance to mineral oils.

EPDM is ideal for outdoor applications because of its excellent resistance to ozone, oxidants, UV exposure and severe weather conditions.

It is highly recommended for applications where the elastomer will have excessive exposure to the environment . General Working Temperature Range: - 45° C to +150° C

Other outstanding characteristics of EPDM RUBBER include excellent color stability, heat resistance, and dielectric qualities.

EPDM is not recommended for applications involving petroleum derivatives.

EPDM is generally attacked by mineral oils, solvents, and aromatic hydrocarbons.

Nitrile, Buna N , or NBR

Nitrile is the most widely used elastomer in the seal industry.

The popularity of nitrile is due to its excellent resistance to petroleum products and its ability to be compounded for service over a temperature range of - 35°C to +120°C . A Modified NBR-Premier has a withstand short term temperature of - 35°C to +200°C .

Nitrile is a copolymer of butadiene and acrylonitrile. it has excellent resistance to mineral oil, greases, water, hydrocarbon fuels, compression set resistance and good elastic properties, it is not suitable to automotive brakes fluid.

Common Rubber Applications :-

NBR- Nitrile is generally resistant to many hydrocarbons, fats, oils, greases, hydraulic fluids and chemicals, but can be attacked by ozone, ketones, esters, aldehydes, chlorinated and nitro hydrocarbons.

EPDM- EPDM is generally known for it's good ozone and water resistance. The material should not be used with mineral oils, solvents or aromatic hydrocarbons

GENERAL RUBBER

CUSTOM MADE ( Minimum Order Quantity , MOQ apply )

CUSTOM MADE ( Minimum Order Quantity , MOQ apply )

≥ 100 meters

≥ 100 meters

This seal is compatible with any 75mm ‘T’ bar roller shutter door