DISTRIBUTION TRANSFORMER RUBBER CORK

NBR RUBBER + CORK = RUBBERISED CORK

Copyright © GSE ONLINE SDN BHD ( 1116968-P ) ALL RIGHTS RESERVED

A) Product Name

Distribution Transformer Rubberised Cork

B) Raw Material

Two types:

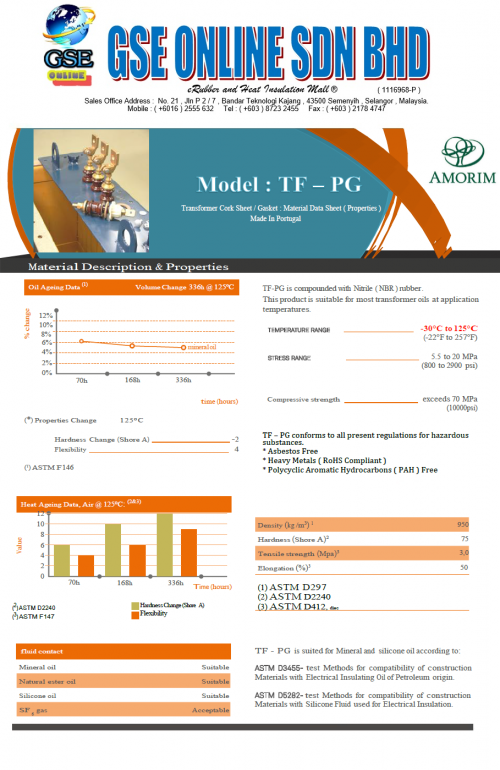

a) TF-PG (TD-1049) ( Cork + NBR)

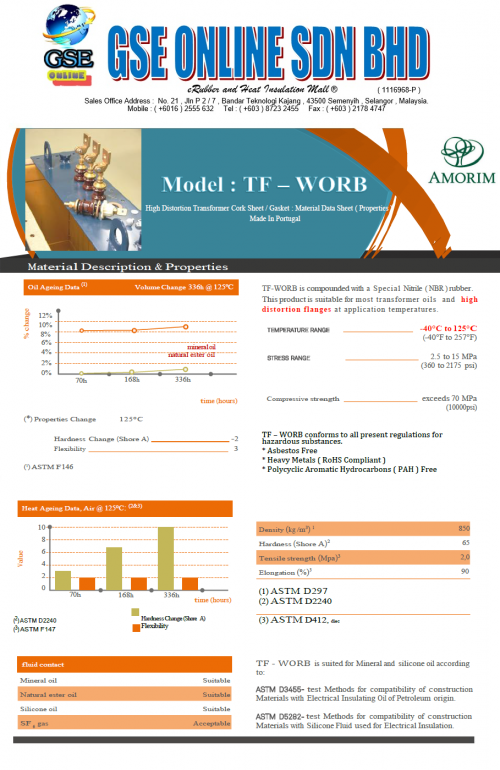

b) High Distortion TF-WORB (TD-1120)(Cork + Special NBR)

C) Purpose

1) Rubberised Corks / Sheets are an excellent “ gasket “material, produced by mixing composition cork and rubber BINDER (i.e. NBR ) to provide unique properties.

2) Rubberised Corks / Sheets are the best substances for transformer applications such as transformer oil gaskets as sealing/gasket material to prevent oil leakage.

D) Scope

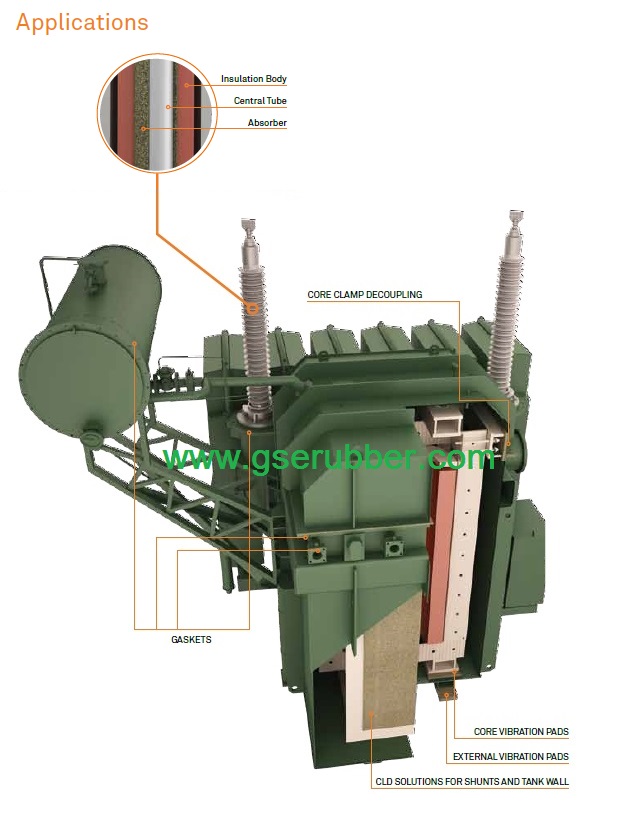

It is ideal for Transformers & switchgear and the General electrical industry, making it a perfect material for a wide range of gasket materials where the application involves oil.

E) Characteristics

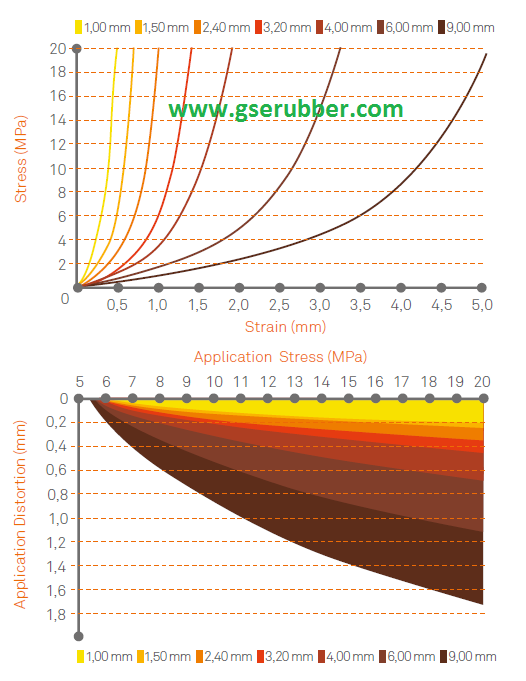

1) Natural Property allows it to recover to its initial shape ( Thickness ) by up to 90% ( ASTM F36). Rubberised Cork is the only material that can compress without lateral spread. This property relieves stress on the flanges to maintain the seal.

2) Asbestos & Polycyclic Aromatic Hydrocarbons ( PAH ) Free & RoHS Compliant.

3) Compression strength exceeds 70 MPa. ( 10,000 psi )

4) High Tensile strength , Stress range from

Model: TF-WORB (TD-1120), 2.5 to 15 MPa. ( 360 to 2,175 psi ) ( ASTM F152 )

Model: TF-PG (TD-1049), 5.5 to 20 MPa. ( 800 to 2,900 psi ) ( ASTM F152 )

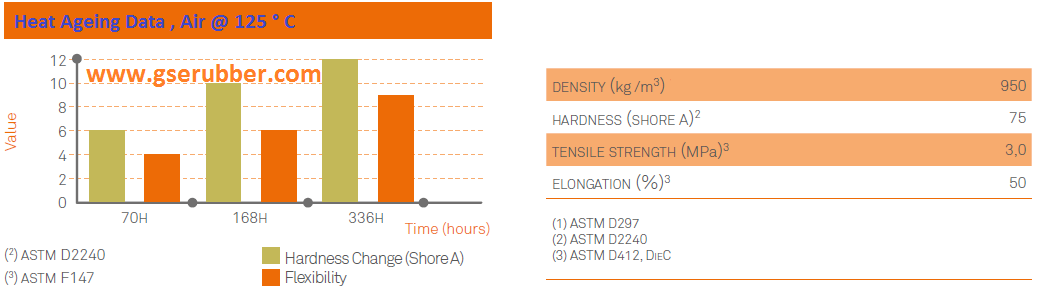

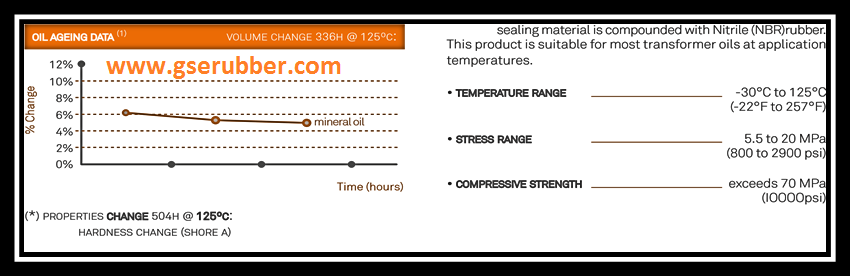

5) Resistance to Temperature from

Model: TF-WORB (TD-1120), temp : -40 ° C to +125 ° C

Model: TF-PG (TD-1049), temp: -30 ° C to +125 ° C

6) Suitable for fluid contact like Mineral Oil, Natural Ester Oil, Silicone Oil & acceptable for SF 6 Gas contact.

7) EXCELLENT in Oil & Heat Resistant.

8) Hardness ( IRHD ) :

Model: TF-WORB (TD-1120) ,65 ± 10 Shore A ( ASTM D2240 )

Model: TF-PG (TD-1049) , 70 ± 10 Shore A ( ASTM D2240 )

9) Colour: Light Brownish (TF-PG/TD-1049) / Dark Brownish (High Distortion TF - WORB/TD-1120)

10) Density : 750~900 Kg/m³ ( ASTM F1315 )

11) Made In Portugal.

F) Specifications

A ) Rubberised Cork Sheets -

Available Thickness : 2mm , 3mm , 4mm , 5mm , 6mm , 6.4mm , 8mm , 10mm & 12mm . ( * subject to ex-stock )

B) Pre-Cut Rubberised Cork Gaskets -

Size: Any available pre-die cutting shapes.

Cork Tree

+

Rubber Binder

* Note : Users need to evaluate suitability on their industries use ( applications ) before placing order from us .

Download Material Data Sheet Model : TF-PG here

Download Material Data Sheet Model : TF-WORB here

Download Material Data Sheet Model : TF-WORB here

Model : TF - PG

2mm & 3mm 4mm, 5mm & 6mm 8mm , 10mm & 12mm